OUR SOLUTIONS

Visual Checks

Defects such as dents, cracks, scratches,

contamination, rust, peel off, etc.

Dimensional Checks

Linear, curved and angular dimensions

which are falling outside tolerance limits

Flexible and independent of colour and coordinate system.

Simpler and faster system deployment. Plug and play.

Supports wide range of cameras and computing hardware options.

Seamless integration with automation and digitization.

Scalable through hassle free ‘No-Code Model Training Environment’

Quality control is the process of separating the bad objects from the good objects.

It has no control over the process & can’t predict any chances of occurrence of a defect.

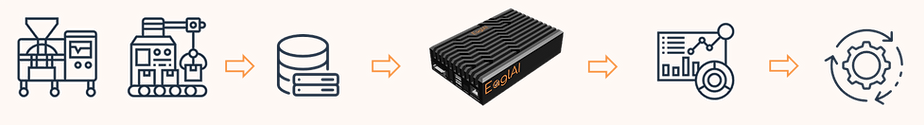

Machines /

Production Line

Process Data

AI-On-The Edge

Processor

Smart Analytics

Dashboard

Process

Improvement

Paradigm shift: Health and Safety is a regulatory necessity,

A workforce motivation and retention tool

An AI driven vision system focused on plant regulatory compliances of Personal Protective Equipment,

Safe Working Practices and Overall Workplace Safety

Early Fire Hazard Detection and

Warning System

Entry Identification for Restricting Unauthorized Access

Ergonomic Posture Estimation for Safe Working Conditions

Smart Analytics Dashboard for Single Point Site Visibility

Personal Protective Equipment Detection and Warning

Moving Vehicle Hazard Collision Warning

EaglAI Train is a versatile, automated and user friendly AI Model training software,

featuring a ‘No-Code Model Training’ Environment

One of the first to launch a ‘No-Code Model Training’ environment.

Simple to understand steps, eliminating requirements of lengthy, costly user trainings.

Quick and easy to add new products and defects making the process very flexible and scalable.

Increased productivity and reduced lead time for every new application development.

Automated workflow. Minimal user inputs.

No need of coding at all.

It works with images for defect detection and numerical data for analytics